FEATURES Science and Engineering

A Brainy Idea

How One Student's Creation Could Help Researchers Better Understand the Zika Virus

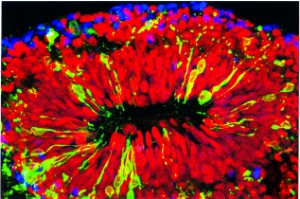

IMAGE: XUYU QIAN/JOHNS HOPKINS MEDICINE

IMAGE: XUYU QIAN/JOHNS HOPKINS MEDICINEA minibrain infected with Zika virus. The virus is shown in green, neural stem cells in red and neurons in blue.

One morning last April, Chris Hadiono, then a first-year engineering student at Case Western Reserve, was studying for finals when he eyed an email with a particularly strange subject line: "Cell Editorial Decision CELL-D-16-00729." Curious, Hadiono took a look. The prestigious research journal Cell was about to publish research that used a "bioreactor" to address one of the biggest public health questions today: How does the Zika virus cause microcephaly (small head size due to abnormal brain development) in newborn babies?

The bioreactor, Hadiono realized, was the very device he had developed two years earlier as a high school intern in the lab of Hongjun Song, PhD, a professor of neurology at Johns Hopkins University. In fact, the work was possible in large part because of the device; without it, Song recently said, "I don't think this [study] would have happened" this quickly.

But until that spring day, Hadiono had no idea that the bioreactor would be used at all, let alone for such an important study. "I was like, 'Wow, they did this with the bioreactor?'" he said.

On April 22, the day the study appeared, Hadiono learned he was listed as a co-author. Ten days later, he texted the online link of a news article that mentioned his involvement to his father, Erwin. "I clicked on it," Erwin remembered, "and I was like, 'Oh my God, this is Chris?'" By May 9, the research news had even spread to the pages of The New York Times.

"I was astounded that I was part of something like this," Hadiono said.

PERSISTENCE AND PASSION

Just how did Hadiono pull off such a rare feat—coauthorship in Cell during his first year in college? To be sure, he didn't grow up in a family of researchers: His parents are first-generation immigrants from Indonesia; Erwin works as an information-technology specialist for IBM, and his mother, Jeane, is an assistant controller at a private equity firm.

PHOTO: ROGER MASTROIANNI

PHOTO: ROGER MASTROIANNIChris Hadiono

They urged their sons to study science. "They really want to make sure that we get the best chances to succeed, especially in fields [with the] most promise, like technology [or] science," said Chris' older brother Matt, who graduated from Case Western Reserve in May with a major in biology.

By middle school, Chris Hadiono had gravitated to science and math. What really sparked his interest was the Authentic Science Research Program at Byram Hills High School in Armonk, New York. The three-year offering allows students to study in depth a research topic that they feel passionate about, and culminates with an internship in a research lab. The Hadionos had moved to Armonk, a hamlet about 40 miles north of Manhattan, specifically for that program.

Just after Hadiono started at Byram Hills in 2011, he watched a video on stem cells in his biology class and was hooked. "I thought it was really cool how [they] can basically repair your body and rejuvenate you," he said.

Then, while reading about stem cells, Hadiono came across a paper by Song and was fascinated by his lab's work: turning human skin cells into stem cells, which, in turn, can be turned into neural stem cells and then into neural tissue used to study human brain development or to model neurological disorders.

Hadiono emailed Song, asking to intern in his lab. Initially, Song didn't respond—in part, he said, because Hadiono was from out of state, which meant more paperwork and the need to arrange housing. But Hadiono persevered and, eventually, Song suggested a phone call.

Excited and nervous, Hadiono plowed through the dozen or so stem cell papers he had read and the notes he had prepared on them. "I wanted to impress him," he said. But Song didn't even ask any questions about stem cells, Hadiono recalled: "He was just like, 'Hey, do you want to come to my lab some time?' I was like, 'Oh, that was way easier than I thought it would be.'"

AN UNEXPECTED CHALLENGE

Hadiono arrived in Song's lab for his six-week internship in June 2014, eager to work on stem cells. But the graduate student assigned to supervise him, Ha Nam Nguyen, said six weeks was too short a time for stem cell work.

Instead, Xuyu Qian, another graduate student, suggested an engineering project. The lab had started using a bioreactor to grow brain organoids or "minibrains"—pinhead-sized 3-D cultures grown from neural stem cells that resemble human brain tissue.

PHOTO: CHRIS HADIONO

PHOTO: CHRIS HADIONOChris Hadiono created this bioreactor in the summer of 2014 at a Johns Hopkins University lab. While the lab had other bioreactors to grow minibrains, the one Hadiono developed allowed scientists to move forward more quickly and inexpensively with their research.

That bioreactor was a soda-can-sized flask with growing minibrains suspended in a culture medium—a nutrient-rich broth designed to keep the cultures alive and growing. A magnetic bar continuously stirred the medium to keep the minibrains floating so they could grow in all directions and improve their oxygen and nutrient intake.

The problem, Qian told Hadiono, was that the device was too big and required too much of the expensive culture medium. The researchers could only do a few experiments at a time, each costing thousands of dollars.

"We were thinking hard—how can we make this simpler, cheaper, smaller?" Song recalled.

Initially, Hadiono was skeptical about what he could contribute. "I felt like I was in way over my head," he said. "None of the stuff I had learned [about stem cells] in the past two years was useful anymore." But wanting to be helpful—and recognizing he wasn't in a position to refuse—Hadiono said yes.

He spent his first week researching existing types of bioreactors, but none seemed that different from what the lab already had.

AN INSPIRED IDEA

Then it occurred to him: Perhaps he could just use the lab's 12-well plastic culture plates, each the size of a postcard with three rows of four circular wells that could hold about a teaspoon of liquid. "I was thinking that each of the wells could act like a bioreactor chamber," he said.

Hadiono just needed to find a way to stir the culture medium continuously in each well. He considered a magnetic stir bar in each well, but that seemed too difficult. Eventually, Hadiono and the two graduate students had the idea of placing a set of interconnected gears on top of the wells that could all then be driven by just one gear connected to a motor.

But most of the required parts didn't exist. They had to be created using 3-D printing—something no one in the lab had ever done. Hadiono said he'd give it a try. Nguyen showed him the software needed to design the parts and told him whom to contact at the university's 3-D printing facility. Then he left Hadiono on his own.

"At first, we didn't think that he would do anything," Nguyen recalled. "We thought he would [just] spend a few weeks learning how to use the software."

But Hadiono learned the basics of the program with the help of YouTube tutorials in just two days. Then, he measured the distances between the wells to make sure the gears would fit, and sent his first designs to the 3-D printer.

Nguyen was surprised. "We thought, OK, if this guy is this good, why don't we just ask him to do more?"

And so they did. Several prototypes jammed because of too much friction, but eventually, Hadiono ordered bearings—rings around the moving shafts of the gears to reduce the friction. A few days before the internship ended, the bearings arrived, and Hadiono, Nguyen and Qian assembled all the parts one last time. They turned the bioreactor on—no glitches, just smooth running of the gears.

"That was really exciting when it finally worked for the first time," Hadiono said. Everybody gathered around, Nguyen recalled. "It was awesome."

PHOTO: GABRIELLA DEMCZUK

PHOTO: GABRIELLA DEMCZUKThis culture plate's 12 wells contain numerous minibrains, which appear as small, dark circles.

AMAZING WORK

When Song saw the device, he knew it was going to work. Hadiono "made this possible, put forward the first prototype in six weeks. It's amazing," he said. The new design made growing the minibrains much cheaper because each well only needed three milliliters of the expensive culture medium—50 times less than the device the lab had been using. And while that device cost $125 and could only be used once, the new version was reusable.

To Song, the fact that a high school student did this makes sense. Unencumbered by previous experience, he said, high school students aren't afraid of failure and are freer to try things than graduate students or postdocs.

After Hadiono left the lab, two high school students, Song's son Max and William Jeang, Hadiono's summer roommate at Johns Hopkins, further improved the device. Jeang had been so intrigued by the project that he interned in the lab the following summer. His contribution was to further increase throughput by designing a shelf that could hold several bioreactor plates on top of one another that could be driven by just one engine.

Eventually, the researchers could grow dozens of minibrain cultures at the same time and grow cultures that resembled different parts of the brain.

Still, to check if their minibrains realistically modeled the human brain, they needed to show that a disease known to affect the brain in a certain way affected the minibrains in the same way.

In late January, Qian recalled, Song came to the lab to ask how to do that. That day, Qian had just seen news stories about how the Zika virus, which is transmitted by the bite of certain mosquitoes, might cause microcephaly in newborn babies. "Why don't we check out Zika?" he said.

Song decided to give it a try. After all, the researchers already had identified the right conditions to grow minibrain cultures that resemble the human cortex—the part affected by Zika virus. What's more, the small wells of the new bioreactor now enabled them to quickly grow enough of the virus to infect them.

It didn't take long. By late April, Cell published the results in the study that listed Hadiono as a coauthor. It showed that Zika virus seems to cause microcephaly by infecting and killing the neural stem cells that give rise to the cerebral cortex. At the time, it was one of the most realistic pieces of experimental evidence for how the virus affects brain development.

"This study was the first to show [human brain cultures] could make all six layers of cerebral cortex," said Jack Parent, MD, a professor of neurology at the University of Michigan, who was not involved in the study. He called the bioreactor device "a fantastic advance to the technique of making cortical organoids."

Song even applied for a patent, listing Hadiono and the other two high school students as co-inventors. And when other labs started to ask him how to build and work with the device, Song arranged a workshop for them in June. Researchers from about a dozen labs from all over the country attended, including a graduate student from Parent's lab.

FROM BIOLOGY TO ENGINEERING

Meanwhile, back in Armonk for his senior year of high school, Hadiono took a new academic direction. He had so much fun with the bioreactor project that he applied to universities known for their biomedical engineering programs. He chose Case Western Reserve, in part because his brother went there.

In the summer before moving to Cleveland, he interned at an electrical engineering company in Armonk, working on a solar cell that automatically follows the sun. He liked the work so much that once on campus, he joined the Humanitarian Design Corps as part of a team that works to provide solar energy to the University Farm.

And now he's considering whether to switch his major from biomedical to electrical engineering.

His plans after college are unclear, he said. He is considering graduate school, but there's another, riskier path he finds intriguing. On a recent trip to New York City, he caught up with an old friend, who co-founded a startup company. "My dream, to be honest, would be if I could be an entrepreneur," Hadiono said. "It sounds crazy, but it also sounds like a lot of fun to have that level of freedom and independence."