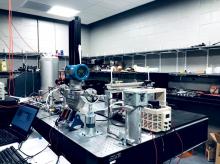

Two-phase Flow Conditioning Loop

The two-Phase flow conditioning loop is designed to conduct a range of flow experiments in boiling and condensation. The loop can use a variety of working fluids and is currently operating with FC-72. The fluid conditioning loop is comprised of a primary loop for the FC-72 and a secondary water cooling loop. A Micropump GA-series gear pump is used to circulate the working fluid in a closed-loop circuit. Exiting the pump, the flow is passed through a regulating valve followed by a Micromotion Coriolis flow meter and one Watlow Cast-X1000 in-line electrical pre-heater before entering the test section. The inline heater is used to fine-tune the vapor temperature at the inlet to the test module (boiling or condensation based on the specific experiment). Exiting the test module, the two-phase mixture is routed first through a brazed-plate water-to-working fluid heat exchanger (condenser), where it is cooled by the secondary water cooling loop, to convert the two-phase mixture back to the liquid state. A detachable fluid reservoir is also part of the flow loop and is also used to deaerate the working fluid before performing tests. The facility is equipped with a NI Labview cDAQ system for data acquisition. The test module, heater and temperature controls, and video camera system are mounted on a rigid optical table.

PIV Facility

The Particle Image Velocimetry (PIV) Setup is designed to measure the instantaneous velocity field in planar cross-sections. It includes an Nd-YAG laser as the light source. The synchronization of the laser and camera is adjusted by means of a National Instruments timing board (Model Number: NI-6602). The camera that is used to acquire PIV images in a Kodak ES 1.0 charge-coupled device (CCD) camera. The system uses PIVACQ and PIVPROC are the PIV software packages which are provided and developed by NASA Glenn Research Center. PIVACQ has a graphical user interface to enter the necessary inputs such as inter-frame time, frame offset, and pulse width, depending on the flow conditions. The facility is useful for obtaining velocity measurements in a variety of two-phase experiments conducted in our laboratory.

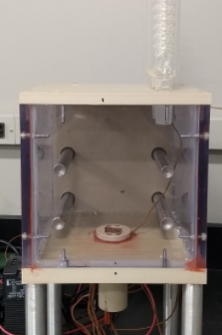

Pool Boiling Facility

The Pool Boiling Facility (PBF) is designed to analyze heat transfer coefficients and critical heat flux (CHF) between different working fluids and boiling surfaces. The PBF includes a pool boiling chamber that can hold approximately 8 liters of the working fluid. This main chamber has four heat cartridges to heat the working fluid to its desired temperature, either at subcooled or saturated conditions. Three sides of the chamber are made of transparent polycarbonate for flow visualization access and the other three sides are made of PEEK plastic material. A copper heater block with cartridge heaters is placed on the bottom PEEK wall to supply the desired heat flux. Temperature measurements are made along the copper block to estimate the heat flux input to the surface. The top of the heater block allows for placement of the sample under investigation with a thermocouple located right below the heated surface for wall temperature measurement. The facility also has pressure transducers and thermocouples to make pressure and temperature measurements of the working fluid.

Flow Visualization Camera

Flow visualization of the two-phase flow features is possible with the use of a FASTCAM SA-Z. A Phantom FASTCAM SA-Z provides megapixel image resolution at frame rates up to 21,000 frames per second (fps) from its highly light sensitive image sensor (monochrome ISO 50,000) with 12-bit dynamic range delivering the ultimate imaging performance. The FASTCAM SA-Z provides frame rates greater than 2 million fps at reduced image resolution and shutter speeds as short as 159 nanoseconds. Illumination is provided on the back side of the test channel by a Multiled-QT light source with capability of 12000 lumens.

IR Camera

Our lab is equipped with an Infra-red camera that we use for obtaining temperature contours on heated surfaces. The specific camera is the FLIR A655sc that features a 640 x 480 pixel microbolometer that detects temperature differences down to <30 mK and temperatures up to 2000 K.