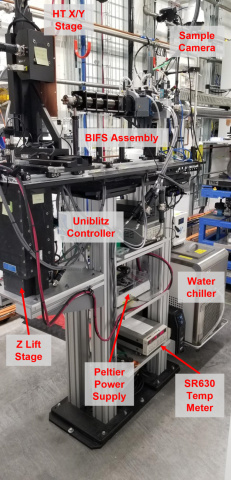

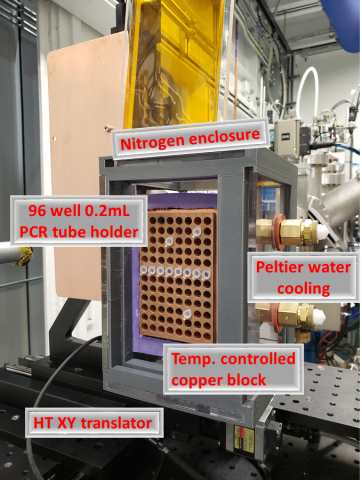

The High-Throughput Endstation (Figure 1), located 30-31 m from the source, has typical X-ray beam sizes of 2.6 – 3.0 mm2, reflecting a diverging beam past the 1:1 focus location of the High-Dose Endstation. These larger beam sizes are well matched to the ~2.5 mm2 diameter of a 5 μL droplet on the bottom of a 200 μL PCR tube, which is the sample format used for all high-throughput footprinting experiments. This endstation is well suited to equilibrium footprinting experiments requiring more modest photon doses than the High-Dose Endstation. As a result, the endstation emphasizes throughput to enable both rapid screening of samples and statistically robust measurements. In addition, samples requiring biosafety level 2 controls can be accommodated with this apparatus, enabling studies of biomedically relevant materials such as mammalian prion proteins or viruses implicated in the common cold.

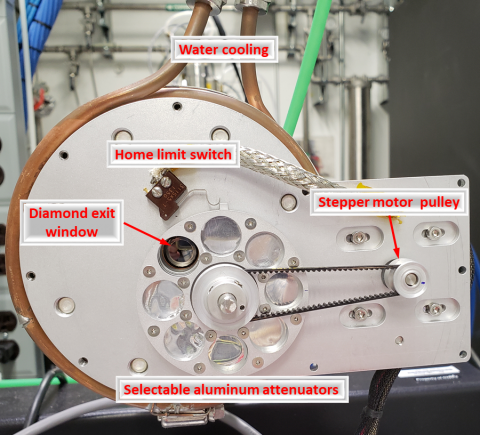

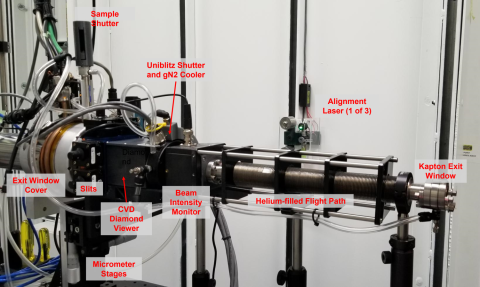

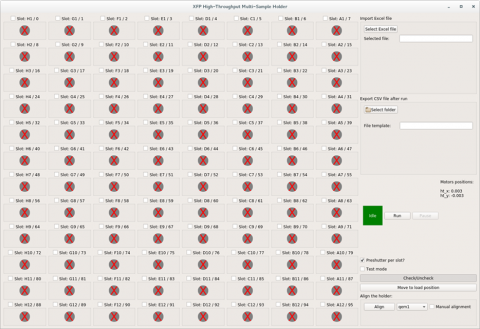

Instrumentation at the high-throughput endstation benefits from considerable investments in automation and diagnostics, including a motorized attenuator wheel (Figure 2), as well as a series of components for monitoring and shaping the beam called BIFS (Figure 3) that is undergoing continuous upgrades and improvements. Sample exposure is controlled by means of a Uniblitz XRS-6 fast shutter capable of exposure times as low as 10 milliseconds. Samples are held by a 96-well high-throughput device (Figure 4) that can accommodate 200 μL PCR tubes, strips, and plates. This device can maintain samples at temperatures ranging from +40° C to -37° C, using recirculating chillers and Peltier cooling as required. A simple, easy to use graphical user interface provides straightforward control of the experiment’s workflow for the user (Figure 5).

It is also possible to perform standard capillary flow experiments at this location, particularly where users desire X-ray doses lower than those of the High-Dose Endstation but at shorter timescales than can achieved with the Uniblitz shutter. Non-standard experiments such as detector development requiring pink beam can also be performed at this endstation, with approval from XFP staff.

Figure 1. Overview of the High-Throughput Endstation with key instrument components.

Figure 2. Motorized beam attenuator wheel aligned with the diamond exit window, showing seven selectable aluminum attenuators (25 – 762 μm). The attenuator position is controlled by a belt-driven pulley attached to a stepper motor, with a home limit switch for position detection.

Figure 3. Overview of the High-Throughput (HT) Endstation equipment. The helium filled Beam Imaging Filtering and Shaping (BIFS) contains the attenuator wheel, a sample shutter, a set of motorized slits to define the beam, a CVD diamond viewer to image the beam, a Uniblitz fast shutter to define sample exposure time, a post-shutter beam intensity monitor, and a helium filled flight path. Lasers are mounted on the wall to facilitate pre-alignment of equipment.

Figure 4. View of the 96-well High-Throughput Device. 5 μL samples in 200 μL PCR tubes, strips, or plates are mounted in the temperature controlled copper block (T range = +40° to -35° C via Peltier cooling), and then automatically aligned and exposed to X-rays. The nitrogen enclosure reduces frosting when running cold. This setup can accommodate samples requiring biosafety level 2 controls.

Figure 5. Overview of the GUI for user control of the HT device. It provides one-button automated alignment and control over exposure conditions for each well. Exposure plans can also be imported as spreadsheets prepared in advance, and useful experimental metadata can be exported for each run.