Looking to 3D print with high accuracy, high resolution, and a variety of materials to select from? Consider submitting an order for Stereolithography (SLA) 3D Printing through our 3D Printing Service.

How to Start

Choose an SLA 3D Printing Material. Our offerings are listed below, under the "Materials and Supplies" section.

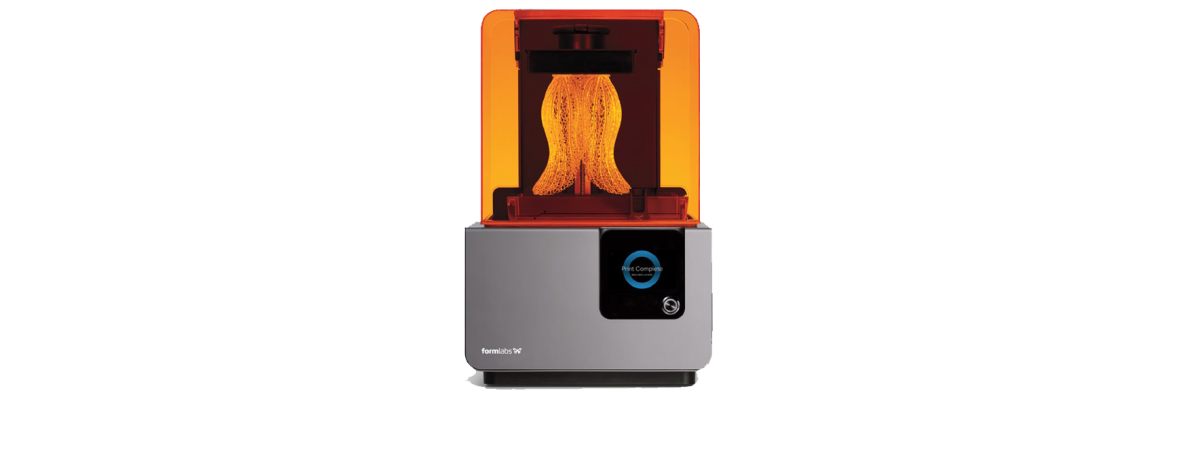

We print on a Form2. Review our Form2 Guidelines to find your maximum build volume, wall thicknesses, printing resolution, and other best practices.

Design for success: Keep printing guidelines and material properties in mind when designing and preparing your parts for printing.

There are a variety of ways to prepare a 3D Model for 3D printing. Here are three common options:

- 3D Modeling: CAD software can make or edit 3D model files.

- 3D Scanning: You can make a printable 3D model from a 3D scan using our Artec LEO or ROMER Arm Scanner.

- Other 3D Model Sources: Open-source 3D models and 3D scans can be found online on databases like Thingiverse. 3D models can also be found online for sale. Check the rules of usage, as not all licenses are the same.

- Submit your STL or OBJ + order information. This form is only for SLA orders.

- Multiple 3D models? Please submit one model per order.

- Review your quote via email. Let us know how to proceed.

- Once approved, most orders are completed within 5-10 business days. You can follow your order's status by looking at our SLA queue.

- A think[box] Prototyping technician will print, wash, dry, and cure your part.

- You will get an email when your part is ready.

- Post Processing: After picking up your print, remove your supports, sand, prime, and paint your parts using FormLab's tips for post-processing.

- Optional Second Cure: If you would like to cure your part after cleaning up your supports, ask a technician in a green apron. Curing takes 30-60 minutes.

Materials and Supplies

Explore the SLA 3D printing materials that think[box] offers, listed below:

The materials list can be read with a screen reader via this link.

For information about specialty engineering resins, please contact us.

SLA Printing Services Technical Information

- Printer: Form2 (formlabs)

- Material: Photopolymer Resin

- Build Volume: 5.7 × 5.7 × 6.9 in (145 × 145 × 175 mm)

- Layer Resolution: 25, 50, 100 microns, 0.001, 0.002, 0.004 inches, 140 microns

- Minimum Unsupported Wall Thickness: .4mm (400 microns)

- Supports: Auto-generated, easily removable

- Review All Form2 Tech Specs

- Note: The various photopolymer resins have different properties which may impact design constraints. Reference the Materials Data Sheet for more information

SLA Printing: Frequently Asked Questions

The cost for printing is determined by the mL of material used.

We have two price points: General resins and high-performance resins.

Included in the price are material costs, consumable costs, and technician processing time.

The Form2 can't mix resin types and can't print parts in full color. Submit a PolyJet order if you need your 3D print to have a mix of materials or be printed in full color.

FormLabs offers more materials than what we provide for our 3D printing services. Please contact us with questions about our resin offerings.

Our Form2 build plate does not support printing directly on the build platform. We print all files with a raft.

Your print will also include supports that you will need to remove manually. Flat prints and cupped prints must be oriented at an angle, a FormLabs practice that leads to the best resolution and success rate in printing.

This setup visually can seem like we print everything with a bit extra resin than is needed. We often get asked if we can reduce the number of supports or print directly on the build plate. You can always ask, but remember, a finished Form2 print looks very different than what comes off of the Ultimaker 2+, PolyJet, and FDM 3D printers, and some support and a raft are needed to ensure success.

We follow FormLab's best printing practices and setup suggestions. Doing so actually keeps our price per mL lower because the rate of failure, stress on the equipment, waste, and equipment part replacement is also much lower.

Our team uses PreForm to prepare our orders for our Form2. It is not necessary to slice your own file for us, but some people like to do so, to be sure of support placement or print orientation.

PreForm is free to download and use. Note: you must specify the material type and Form2 printer when preparing a sliced file, or your settings will not be compatible with our printer and your material.

After orienting your file and generating support, save and include your PreForm file in your initial order request. Be sure to mention this in the comments as well.

We may need to make changes to your file. We will let you know if we need to make any changes.

Most 3D printing submissions are typically ready for pick up within 7-10 business days.

- After submitting your order, you will receive a quote that you must approve before we print. Typically we will send you a quote within 3 business days.

- Keep an eye out for emails with follow-up questions about your file, material choice, or any other issues with your print. We will not proceed with printing your order without getting those clarifying answers from you.

- You may follow your order's status and progress on our Form2 Public Queue.

- A note about the print queue: Some SLA prints take a couple of hours, and some take a few days. We process multiple orders together whenever possible, but large prints can cause delays. We only have one Form2 printer, and it has a small build volume, so plan ahead and give yourself extra time.

Yes! We have a number of tools that are free to use. You will need to bring your own paint, putty, or any other materials necessary for your post-processing needs, however. Check out FormLab's optional post-processing info page to learn how to best clean up a Form2 part.

- On Floor 3, we have hand tools that are often used to remove support and clean up parts, such as diagonal cutters, tube reamers, pliers, and dry sandpaper.

- Floor 3 also has a fume hood with a vacuum chamber for making molds and casting from 3D Prints.

- On Floor 5, we have a paint room complete with drying shelves for temporarily storing your print when it is wet.