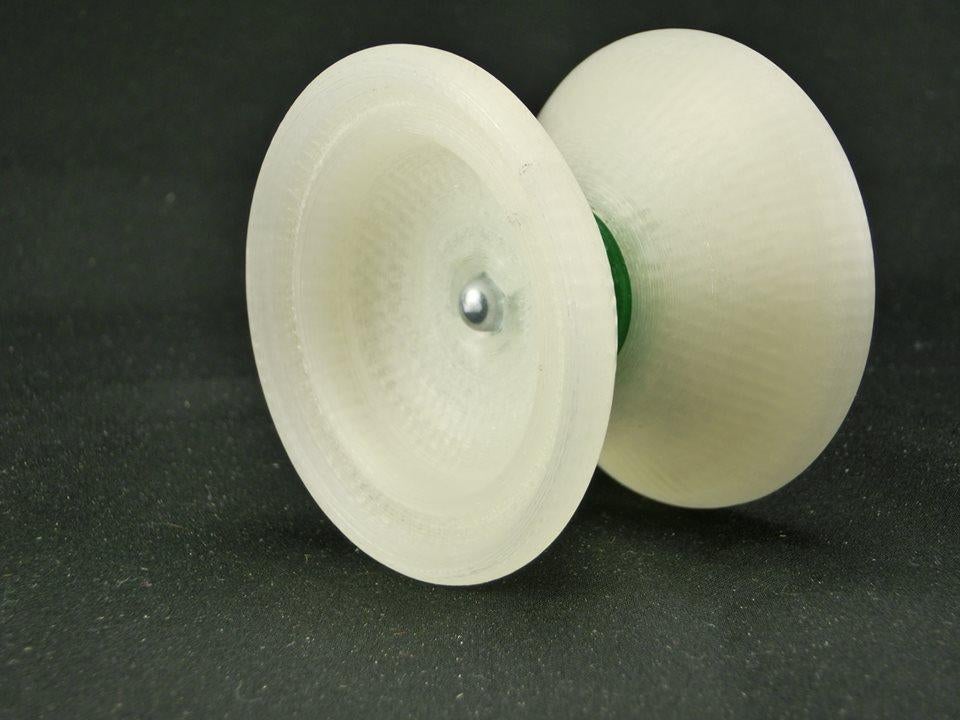

This novel and patent-pending design for an inexpensive 3D printed competition-grade yoyo uses a single material, and achieves a high moment of inertia by changing the geometry in ways that would be impossible without 3D printing. The main difference in this design is the internal variable density rings that would be very difficult to do any other way than 3D printing. By maintaining a high fill density and high resolution, the yoyos are rotationally symmetric with high moments of inertia and mass equal to that of a standard competition grade yoyo, while having a net production cost of less than 20 dollars per yoyo, factoring in everything from the string, to the box, to the bearing.

Contact:

Zach Lerner

Vince Cozza, vincent.cozza@case.edu