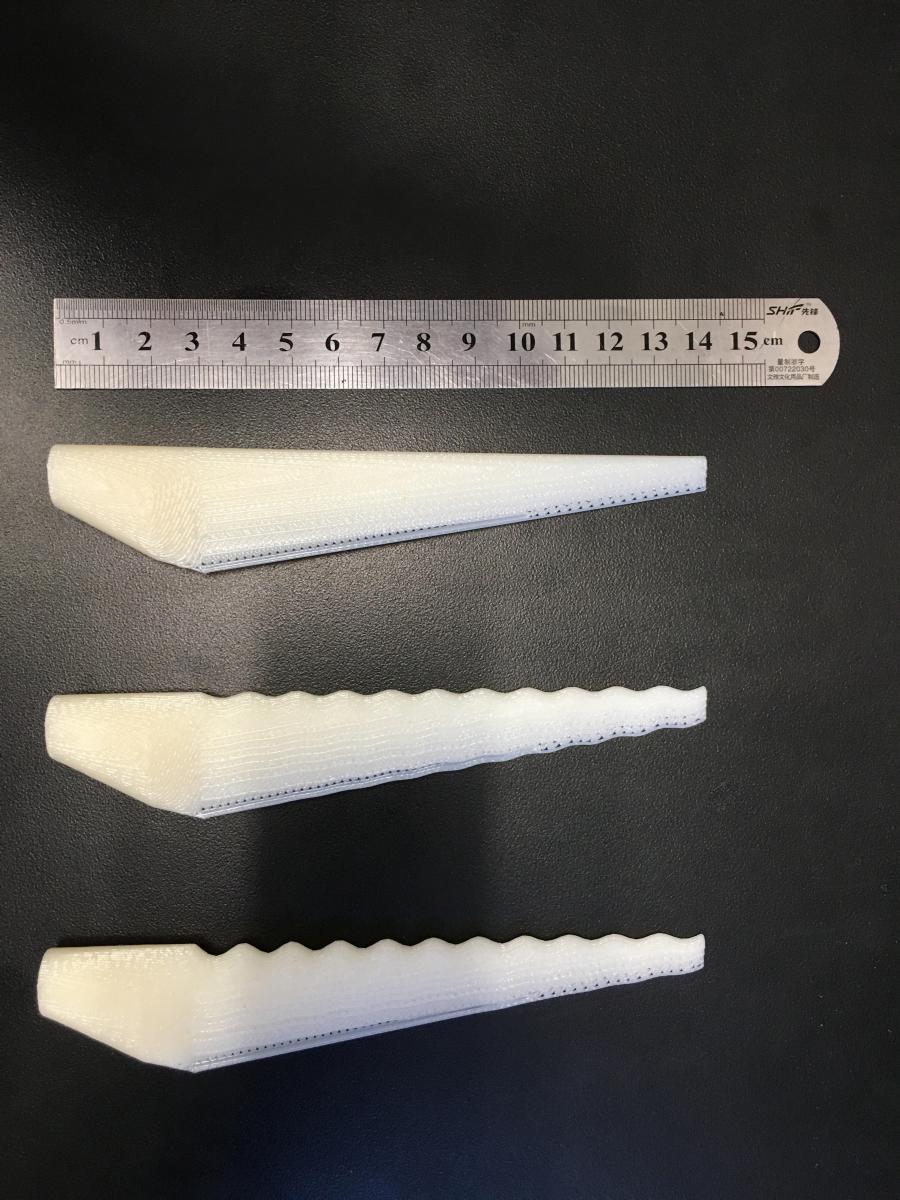

Researchers added tubercles to the leading edge of wind turbine blades for a 4.8% increase in lift-to-drag ratio. This increase in performance is expected to translate into increased energy output versus conventional blades. After successful computer simulations, the researchers used the ShopBot CNC table router to machine a fiberglass mold out of machinable wax, which was then used to cast the turbine blades. These prototypes were then tested in a wind tunnel facility to verify the increased performance predicted by the computer simulations.

Contact:

Jiale Li, jxl780@case.edu